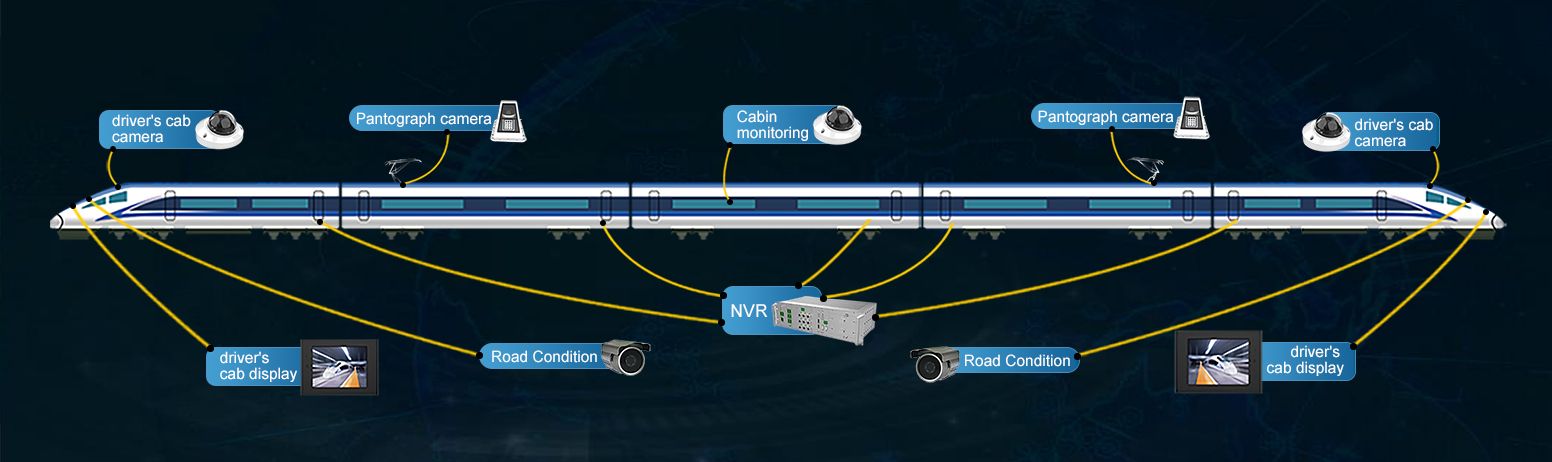

Overview of pantographs for China EMU

2023-02-02 15:10The CRH series has been the basis for continuous innovation in high-speed trains in china. Pantograph as a crucial electrical connection component have also evolved in this process.The pantographs play a important role in receiving high power from the contact network for the single-phase AC 25kV high voltage power required by the rolling stock. The total traction power required by high-speed trains is much greater than that of ordinary trains. At higher speeds, the air resistance also increases. Considering the requirements of reducing air resistance and noise, the number of pantographs on high-speed trains should not be too many. For 8-car trains, China adopts the single-arch pantograph method, i.e., only one pantograph is used during the operation of the trains and considering the requirements of reliability and redundancy, two pantographs are installed on each train. When the rolling stock is in process, one of the pantographs can be selected to be raised and the other pantograph folded.

The pantograph sliding plate will be worn during operation and produce powder, which may affect the insulation of the insulator. The insulation of insulators and the damaged parts may affect the safety of running vehicles if they fail during operation, so in the actual process, the rear pantograph is preferred when selecting pantographs. Between the two bows, the simultaneous rise is avoided by electrical interlocking.

Whether the rolling stock can achieve high-speed traction operation is directly related to the state of the pantograph so that the rolling stock will have the following technical requirements for the pantograph.

The height of the contact network is inconsistent. To ensure reliable contact of the pantograph system, the pantograph and the contact network should maintain a specific contact force. The size of the contact force will affect the service life of the pantograph. When the contact force is too large, the wear and tear of the softer sliding plate increase compared with the contact network line. At the same time, when the contact force is too small, the offline between the pantograph and the network will quickly occur, which affects the safety of traffic. Therefore, when commissioning the pantograph, the contact force must be adjusted and moderate.

The rise and fall of the pantograph is achieved by a hinge system between the upper and lower arms of the pantograph. To ensure an excellent dynamic adjustment performance of the pantograph, the weight of the upper and lower arms should be as light as possible. Several commonly used pantographs in China adopt an aluminum alloy structure.

The pantograph and the contact network are in direct contact through the skid plate. Because the contact network adopts the "zigzag" structure, the skid plate will move back and forth during the operation of the rolling stock. Therefore, the sliding scale's material, system, and length have to meet the requirements. China mainly uses carbon skids to achieve good electrical conductivity and wear resistance.

In both bows raising and lowering, the speed of the pantograph should be fast and then slow to prevent bouncing in the process of bow raising and shock in the process of bow lowering, which is achieved by adjusting the dampers on the base frame.

If a fault occurs during the operation of the pantograph and is not handled in time, it may further expand the fault or damage the contact network. Therefore, the pantographs must be designed with an automatic lowering function.

This paper will introduce several pantographs used in CRH series rolling stock.

1 DSA250 pantograph

The DSA250 pantograph is suitable for CRH1, CRH2, and CRH5 cars. The entire pantograph adopts a single-arm structure and is equipped with double carbon skids to ensure good conductivity during operation. The pantograph is mainly composed of the bottom frame, upper and lower arm, and bowhead. To realize the technical requirement of lightweight, the moving parts of the pantograph and the bowhead are aluminum alloy. To prevent excessive wear of the carbon sliding plate, the carbon sliding plate is designed with a hollow structure and connected to the pressure switch on the control valve plate through an air circuit. The pressure switch is triggered when the wear limit leaks (i.e., when the compressed air value drops to 2.5 bar). The ADD function is activated, which eventually causes the pantograph to drop rapidly and realizes the lowering protection.

2.SSS 400+ Pantograph

The SSS 400+ pantograph is suitable for CRH3 type cars and is also a single-arm type with a double sliding plate structure. A complete pantograph consists of the pantograph itself and the air control panel installed in the car.

The control of the pantograph is achieved through the network. The driver operates the pantograph lift switch to trigger the solenoid valve, which opens the air circuit and lifts the pantograph by compressed air. When a fault occurs in the pantograph operation, such as a rupture of a carbon skid plate abrasion over the limit, the fast descending valve is triggered to lower the pantograph quickly. Meanwhile, the pressure switch transmits the relevant signal to CCU and then sends the applicable fault code to HMI after diagnosis and processing by CCU. At the same time, the pressure switch transmits the relevant signal to CCU. After CCU diagnoses and processes, it then sends the relevant fault code to HMI, realizing the human-machine exchange of information and reminding drivers to change the pantograph in time.

3.CX Active Control Pantograph

CX pantographs are suitable for CRH380 B-type cars, different from ordinary pantographs. First, the pantograph adopts a single slide structure while changing the slide material to a copper-impregnated carbon slide to extend the service life. Secondly, the pantograph control unit (PCU) is added to adjust and control the pantograph network's contact force during the pantograph's dynamic operation. Again, new synthetic materials were used for the arch body, making the pantograph 30%-40% lighter; finally, a higher precision air conditioning device was adopted. As a result, the CX pantograph is simple in structure, lightweight, adjustable in dynamic contact force, and more reliable.

The pantograph itself is driven by compressed air. Compressed air is supplied from the vehicle piping and enters the pantograph airbag via the APIM unit. The airbag generates torque by compressed air and is hinged by a cam and a flexible joint shaft to lift the bow. When lowering the pantograph, the compact airline is shut off, and the pantograph is reduced by its weight. If the compressed air supply is interrupted or the low voltage power supply fails, the pantograph will automatically lower by activating the ADD device.

The operating principle of this pantograph is similar to the DSA250 pantograph, except that the dynamic characteristics of this pantograph can be adjusted. The adjustment of the dynamic features of the pantograph is achieved using a two-stage suspension connected to the damper.

An airbag accomplishes the first stage of suspension. The pantograph control unit ensures that the pressure of the airbag remains constant and independent of the height of the pantograph. The second stage of suspension is adjusted by a spring in the bowed head. A two-stage suspension can achieve reasonable dynamic adjustment of the pantograph.