Locomotive 360° Panoramic Monitoring: How Many Blind Spots Are Still Costing You Claims?

2026-02-04 20:47You win the tender.

You deliver the CCTV.

Then a side-impact, trespass, or depot incident happens—right where the camera didn’t see.

And suddenly the problem isn’t “video quality.”

It’s evidence gap, acceptance dispute, and who pays.

If you’re a system integrator or engineering company, you don’t want “more cameras.”

You want less risk.

Faster acceptance.

Cleaner handover.

And a solution that helps you get the next project—because the operator trusts you.

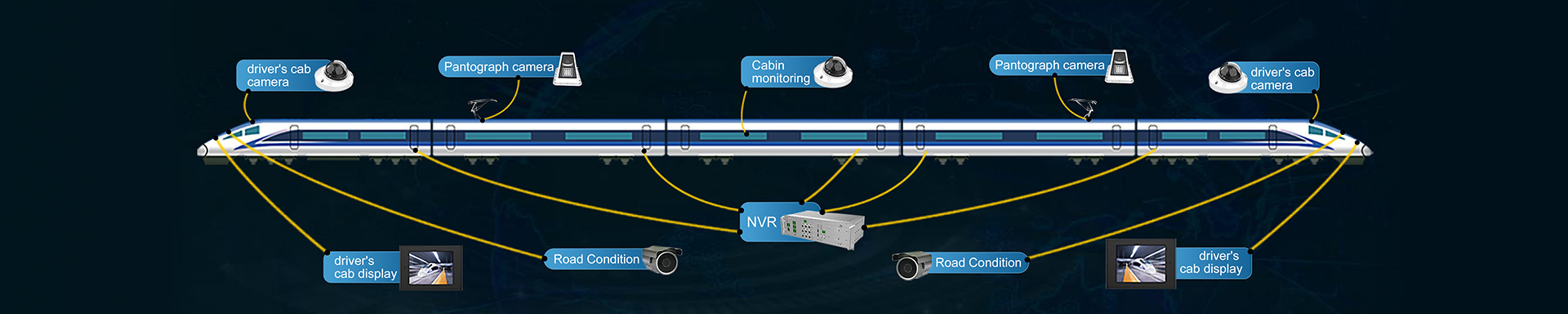

This is exactly why we launched TIENUO’s Locomotive 360° Panoramic Monitoring concept: a rail-ready approach to cover front + rear + both sides, with special attention to high-risk side zones like the fuel tank, without turning your project into a wiring nightmare.

Why do side blind spots keep breaking projects?

Because locomotives operate in messy realities:

depot maneuvering,

close-pass infrastructure,

coupling operations,

unauthorized access,

low-light glare,

and “it happened on the side” incidents.

Traditional “front + rear” CCTV makes you feel covered.

But operators don’t pay for feelings.

They pay for evidence.

And the worst disputes usually happen in zones that are:

along both sides,

near frequent human activity,

and hard to watch continuously—especially the fuel tank area.

What makes a locomotive 360° upgrade actually usable?

Here’s the truth from the field:

If drivers won’t use it, it becomes “just another recorder.”

If maintainers hate it, it becomes downtime.

If acceptance is unclear, it becomes a contract fight.

A 360° approach becomes useful only when it delivers:

one-view situational awareness,

fast switching to details,

event evidence packaging,

and integration flexibility for the integrator.

TIENUO’s concept is built around a stitched panoramic view designed to reduce blind zones and improve operational visibility.

Which key features matter to integrators (not marketing)?

Below are key differentiators only—so you can sell outcomes, not a hardware list.

1) “See it all” panoramic coverage (the real painkiller)

A stitched surround view covers the locomotive environment in a single operational perspective—so operators stop asking, “Why is that area not visible?”

This directly reduces:

blind-spot incidents,

post-event arguments,

and acceptance rework.

2) Evidence package automation (what saves you in disputes)

When an abnormal event triggers, the system can save:

alarm screenshot,

plus 1 minute before and after video evidence.

This is the difference between:

“Give us the footage” (panic),

and “Here is the evidence package” (control).

3) Edge intelligence that supports “prevention,” not only playback

Instead of passive recording, the system supports intelligent alarm logic for abnormal events (e.g., foreign-object intrusion), with audible alerts for timely response.

That’s how you sell risk reduction instead of storage capacity.

4) Driver-friendly viewing (because usability = adoption)

A practical HMI flow:

default panoramic view,

one-touch switching to any channel’s HD view.

When drivers actually use it, operators feel the value daily—without waiting for an incident.

5) Integration-ready for system integrators

Compatibility reduces project friction.

Key integration points include:

ONVIF support for platform interoperability.

Interface capability to coordinate switching logic with onboard systems.

This helps you fit the solution into existing rail VMS ecosystems.

6) Rail-grade camera performance where failures usually happen

This matters when your project runs through tunnels, snow, glare, wash-down, dust, and vibration.

The camera-level capability highlights include:

5 MP clarity

120 dB WDR for strong backlight/tunnel transitions

IP69K environmental protection

Wide operating temperature (–30°C to +75°C)

How do you turn this into a tender-winning story and real inquiries?

Most competitors sell “cameras.”

You should sell risk outcomes.

Here are 5 inquiry-driving angles that work (especially for integrators and contractors):

“Eliminate side blind spots—especially high-risk zones.”

“Deliver an evidence package automatically (pre/post) to reduce disputes.”

“Driver-ready panoramic view + one-touch detail switching.”

“Integration-ready (ONVIF) for your existing platform.”

“Rail-grade survivability: WDR + IP rating + wide temperature.”

Conclusion

If your current CCTV design still leaves side blind zones, you’re not buying “security.”

You’re buying future disputes.

A locomotive 360° upgrade is valuable when it:

improves operational visibility,

automates evidence packaging,

integrates smoothly,

and survives rail conditions.

That’s the difference between “a recorder” and “a system operators trust.”