Resources

This blog is written for railway system integrators, contractors, and railcar manufacturers who are tired of CCTV projects being judged by “camera count” instead of risk reduction. From the buyer’s viewpoint (like Mark, a purchasing manager), it focuses on the real pain points behind locomotive incidents: side blind spots, especially around high-risk zones like the fuel tank, plus the costly consequences—acceptance disputes, claims, and missing evidence. Instead of presenting a long technical proposal, the article highlights only the key differentiators that drive inquiries: a stitched 360° panoramic view to reduce blind areas, driver-friendly switching for real operational use, edge intelligence for abnormal event alerts, and automatic evidence packaging (including pre/post event video) to protect integrators when incidents happen.

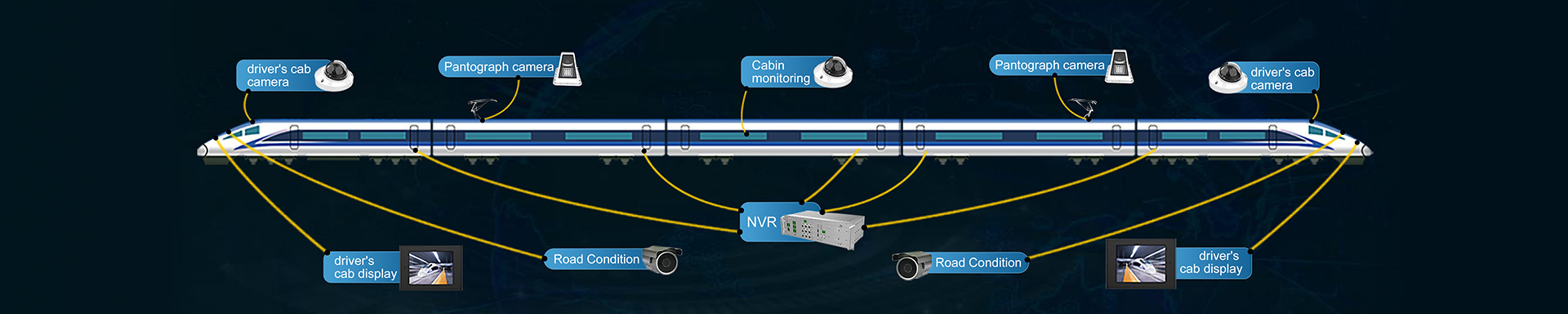

Pantograph video/condition monitoring has become a “must-have” for electrified railways across APAC because it helps prevent dewirement events, reduces manual inspections, and enables condition-based maintenance. Below are five brands that stand out in APAC deployments or APAC-ready product maturity—based on publicly available product pages, brochures, and railway project documentation.

Tienuo Intelligent provides advanced pantograph monitoring systems that leverage AI, 5G, and big data to ensure real-time detection of faults such as spark events, structural abnormalities, and foreign objects. These systems help improve railway safety and operational efficiency by adhering to essential global standards such as EN 50155, EN 50153, and IEC 61373. Designed to operate in extreme conditions (-40°C to +80°C), Tienuo's solutions are trusted by rail fleet operators, OEMs, and engineering firms worldwide to ensure the safe operation of rolling stock and infrastructure.

Discover how our advanced Pantograph Video Monitoring and Intelligent Analysis System revolutionizes high-speed rail safety with real-time AI detection of faults like tilting, sparks, and structural anomalies. Tailored for integrators, manufacturers, and rail experts, this innovative solution minimizes downtime, enhances reliability, and integrates seamlessly with global networks – powering the future of efficient, secure transportation.

The article explores the Pantograph Video Monitoring System and its key features, designed to improve the safety and operational efficiency of high-speed rail networks. This system leverages AI-based analysis to detect faults like electrical arcing, pantograph tilting, and structural deformations in real-time. The intelligent system offers predictive maintenance, ensuring timely interventions to avoid major disruptions. Equipped with high-resolution cameras and designed to work in varying lighting conditions, it maintains operational reliability. The predictive maintenance algorithms, combined with event-based video tagging, streamline fault analysis and help reduce downtime. Compliant with industry standards, the system supports 24/7 video recording and offers flexible storage options, including local and cloud-based solutions. The system's modular design ensures scalability, making it adaptable for future needs in railway surveillance. The content focuses on how this technology transforms railway operations, making them safer and more efficient through advanced data processing and real-time alerts.

This article explores the explosive growth of the global railway safety monitoring market, projected to reach $50 billion by 2033 with a 6.5% CAGR, driven by advancements in AI, 5G, and big data. From a seasoned industry perspective, it delves into key drivers like urbanization and regulatory shifts, highlights transformative technologies, emphasizes the competitive edge of customization offered by TIENUO, and urges system integrators, engineering firms, and rail manufacturers to prepare strategies for seizing opportunities in this evolving sector.

TIENUO's HD System Ensures Clarity and Durability in Harsh Rails" directly tackles railway surveillance pain points—like low-light blurs, extreme weather failures, voltage fluctuations, vibrations, and integration issues—for integrators, manufacturers, contractors, and providers. It showcases the HD Video Monitoring System with key specs: ≥0.005 LUX low-illumination, 1920x1080@30FPS resolution, IP68 ruggedness, -40℃ to 75℃ tolerance, DC 8-18V voltage handling, H.264/H.265 compression, and expandable AI features (recognition, IP auto-config, WDR, noise reduction, OSD). The full kit covers driver's cab, road conditions, mechanical/electrical rooms, integrating AI for real-time risk prediction, reduced downtime, and cost savings. Backed by certifications and patents, it offers customization over competitors' reactive solutions.

This article highlights its cutting-edge Pantograph Intelligent Analysis System, designed to revolutionize railway safety and efficiency. With over 20 years of expertise, the company integrates AI, 5G, and big data to offer real-time fault detection, including pantograph posture issues, arc/flashover events, and environmental adaptability. The system ensures minimal downtime and reduced maintenance costs through edge AI and fault video playback. Trusted by global leaders like CRRC, TIENUO’s solution is a game-changer for system integrators and railcar builders.

The leap from analog to HD has reshaped railway video surveillance. It amplifies safety and efficiency. For integrators, manufacturers, and contractors, it's a game-changer. TIENUO's certified offerings, including IRIS and CRCC, lead the charge. Join the upgrade wave. Reach out for personalized consultations. Secure your railway's future.

The Integrated Locomotive Surveillance Hub redefines rail safety with military-grade resilience. Engineered for diesel locomotives operating in extreme environments (-40°C to +70°C), this AI-driven powerhouse combines dual NVR processors, patented anti-vibration tech, and 16-channel 1080p@30fps recording. Its heated 2TB HDD, DC 110V direct input, and driver fatigue detection outperform standard systems, proven across 18 countries. CRCC/IRIS-certified, it turns blizzards, vibrations, and voltage swings into non-events.