Revolutionizing Railway Safety: How AI-Powered Pantograph Monitoring Systems Are Transforming Train Operations

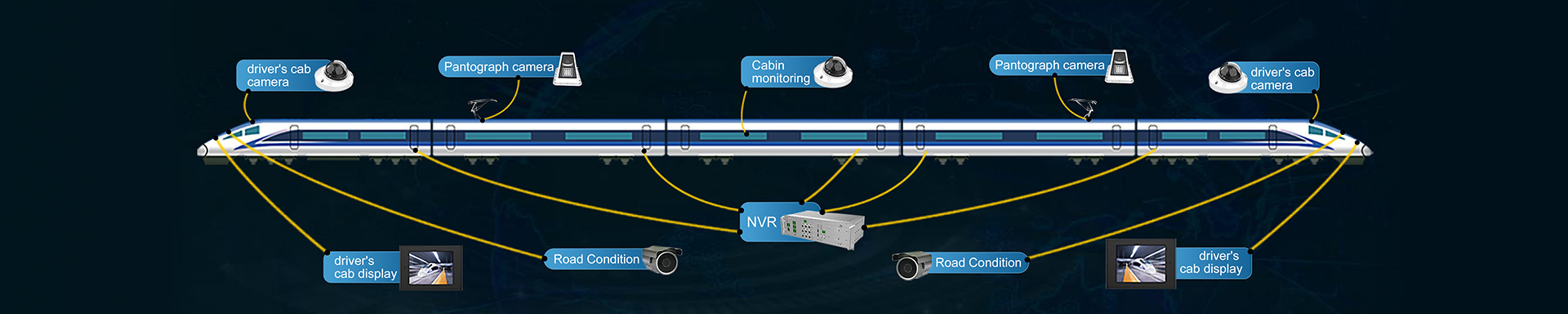

2025-09-02 19:53In the high-speed rail industry, ensuring the seamless operation of pantographs—the vital link between trains and overhead power lines—is paramount. Traditional manual inspections often fall short in detecting subtle faults that can lead to significant disruptions. This is where intelligent pantograph video monitoring systems come into play, offering real-time, AI-powered surveillance to preemptively identify and address potential issues.

Table of Contents

Key Features of Intelligent Pantograph Video Monitoring Systems

Modern pantograph video monitoring systems are equipped with advanced features to ensure comprehensive surveillance:

AI-Powered Fault Detection: Utilize deep learning algorithms to identify issues such as pantograph tilting, structural deformations, and electrical arcing.

Real-Time Alerts: Instantaneous notifications for detected anomalies, enabling prompt maintenance actions.

High-Resolution Imaging: Capture detailed visuals of pantograph operations, aiding in accurate fault diagnosis.

Environmental Adaptability: Designed to function effectively under various weather conditions, ensuring consistent performance.

These features collectively enhance the reliability and safety of railway operations.

Performance in Varying Lighting Conditions

Intelligent pantograph monitoring systems are engineered to perform optimally across different lighting environments:

Low-Light and Nighttime Operation: Equipped with infrared illumination and high-sensitivity sensors to maintain clear visibility in darkness.

Dynamic Exposure Adjustment: Automatic adaptation to sudden changes in lighting, such as entering tunnels, to ensure consistent image quality.

Glare and Reflection Mitigation: Advanced algorithms to reduce the impact of reflections and glare, maintaining image clarity.

These capabilities ensure uninterrupted monitoring regardless of ambient lighting conditions.

Storage Capabilities and Data Access

Efficient data management is crucial for effective monitoring:

Continuous Video Recording: Supports 24/7 recording, capturing all pantograph activities for thorough analysis.

Event-Triggered Recording: Automatically stores footage associated with detected anomalies for post-event review.

Local and Remote Storage Options: Offers both onboard storage solutions and cloud-based access for flexible data retrieval.

Data Retention Policies: Configurable settings to manage storage capacity and ensure critical data is preserved.

These features facilitate efficient data handling and accessibility.

Compliance with Railway Industry Standards

Adherence to industry standards ensures system reliability and safety:

EN 50155: Compliance with electronic equipment standards for railway applications.

EN 50121: Conformance to electromagnetic compatibility requirements.

ISO 9001: Quality management system certification.

ISO 14001: Environmental management system certification.

ISO 45001: Occupational health and safety management system certification.

These certifications affirm the system's commitment to quality and safety.

Camera Durability and Maintenance Requirements

Ensuring long-term reliability involves:

Rugged Design: Cameras are built to withstand harsh environmental conditions, including extreme temperatures and vibrations.

Self-Cleaning Mechanisms: Incorporation of wiper systems to maintain lens clarity in adverse weather.

Maintenance Alerts: Automated notifications for required maintenance tasks, such as lens cleaning or system calibration.

Predictive Maintenance: Utilization of system diagnostics to forecast potential failures before they occur.

These measures ensure sustained performance and minimize downtime.

Predictive Maintenance through AI Analysis

Leveraging AI for proactive maintenance:

Anomaly Detection: AI algorithms analyze operational data to identify deviations from normal behavior.

Trend Analysis: Monitoring of performance trends to predict potential failures.

Maintenance Scheduling: AI-driven insights assist in planning maintenance activities at optimal times, reducing disruptions.

Resource Allocation: Efficiently directing maintenance resources based on AI-generated priorities.

This approach enhances system reliability and reduces operational costs.

Event-Based Video Tagging for Incident Review

Facilitating efficient incident analysis:

Automated Tagging: System-generated labels for video segments associated with detected anomalies.

Searchable Metadata: Indexed video content for quick retrieval based on event type or timestamp.

Integration with Maintenance Systems: Seamless linking of video footage to maintenance records for comprehensive analysis.

User-Defined Tags: Allowing operators to add custom labels for specific observations.

These features streamline the incident review process and support effective decision-making.

Edge Computing for Efficient Data Processing

Enhancing data processing capabilities:

Local Data Analysis: Processing data at the source reduces latency and bandwidth usage.

Real-Time Decision Making: Immediate analysis enables prompt response to detected anomalies.

Reduced Data Transmission: Only relevant data is transmitted, optimizing network resources.

Scalability: Edge computing allows for easy expansion of monitoring capabilities across the network.

This approach ensures timely and efficient data handling.

Scalability and System Integration

Adapting to evolving needs:

Modular Architecture: Flexible system design to accommodate future expansions.

Interoperability: Compatibility with existing railway infrastructure and systems.

Centralized Management: Unified platform for monitoring and controlling multiple units.

Cloud Integration: Utilization of cloud services for data storage and analysis.

These features support the growth and adaptability of railway operations.

Conclusion

Intelligent pantograph video monitoring systems represent a significant advancement in railway safety and efficiency. By integrating AI-driven analysis, real-time monitoring, and predictive maintenance, these systems proactively address potential issues, ensuring uninterrupted service and enhanced safety. For stakeholders in the railway industry, adopting such technologies is a strategic move toward modernizing operations and safeguarding infrastructure.